Facilities

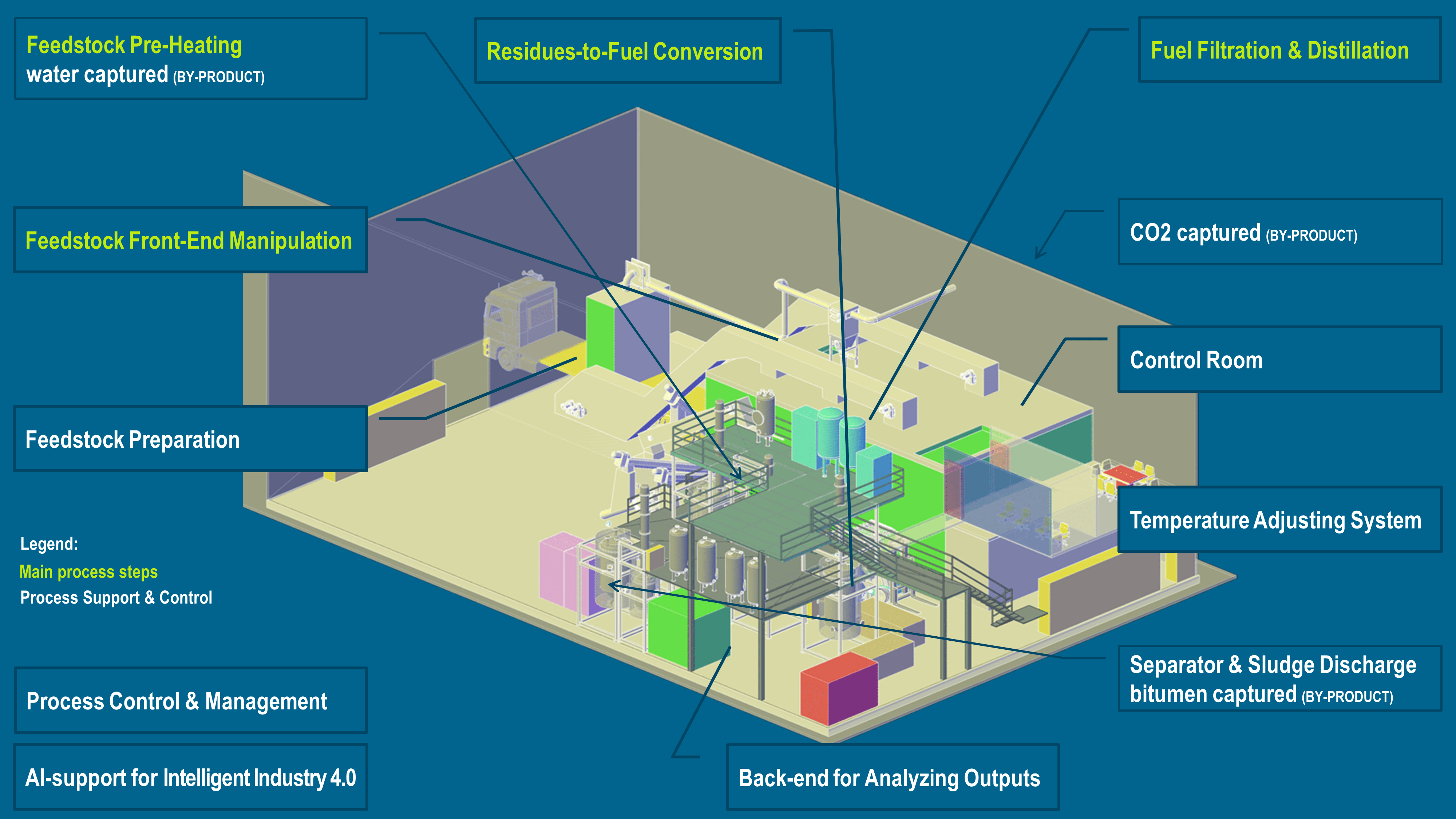

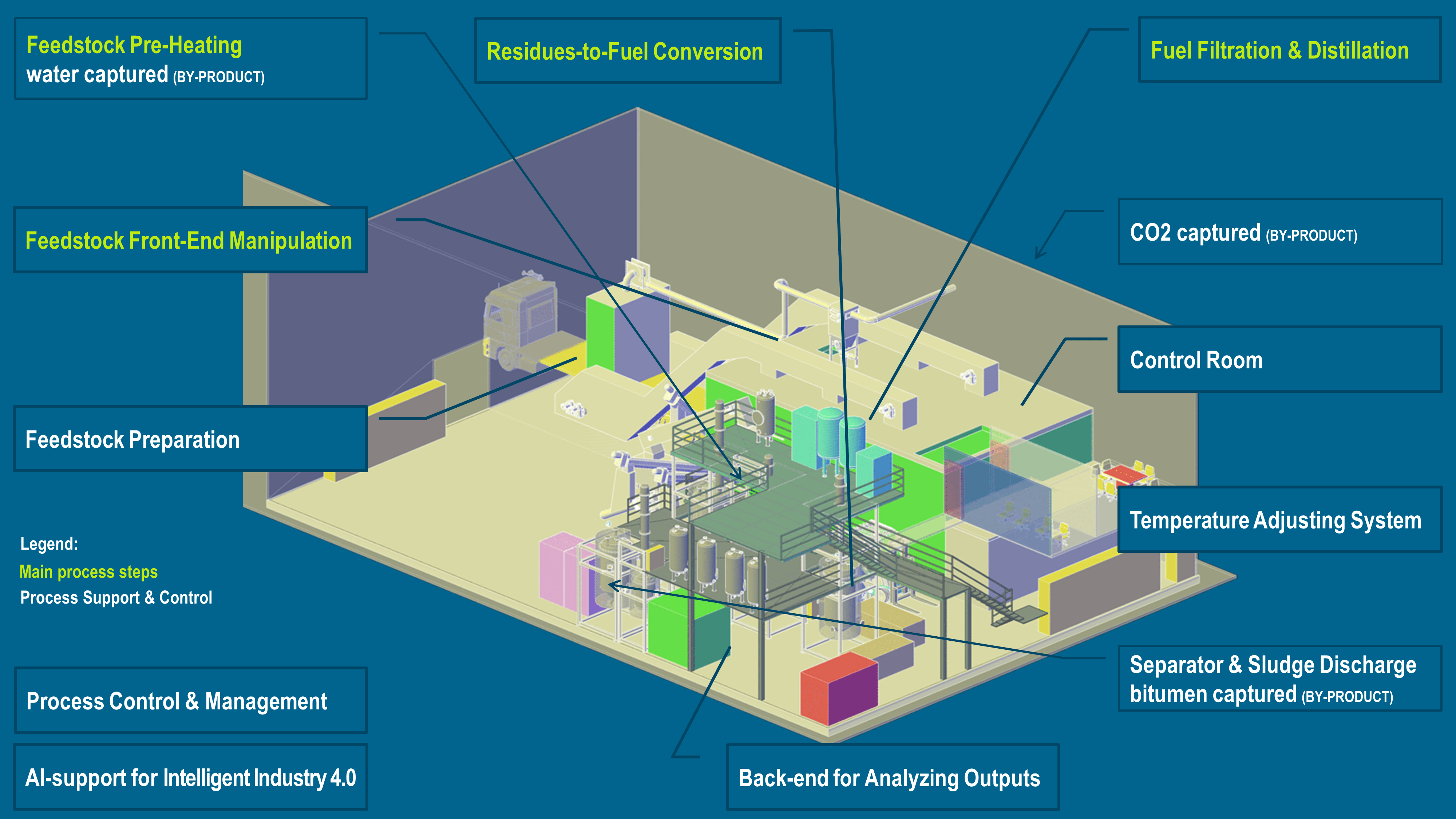

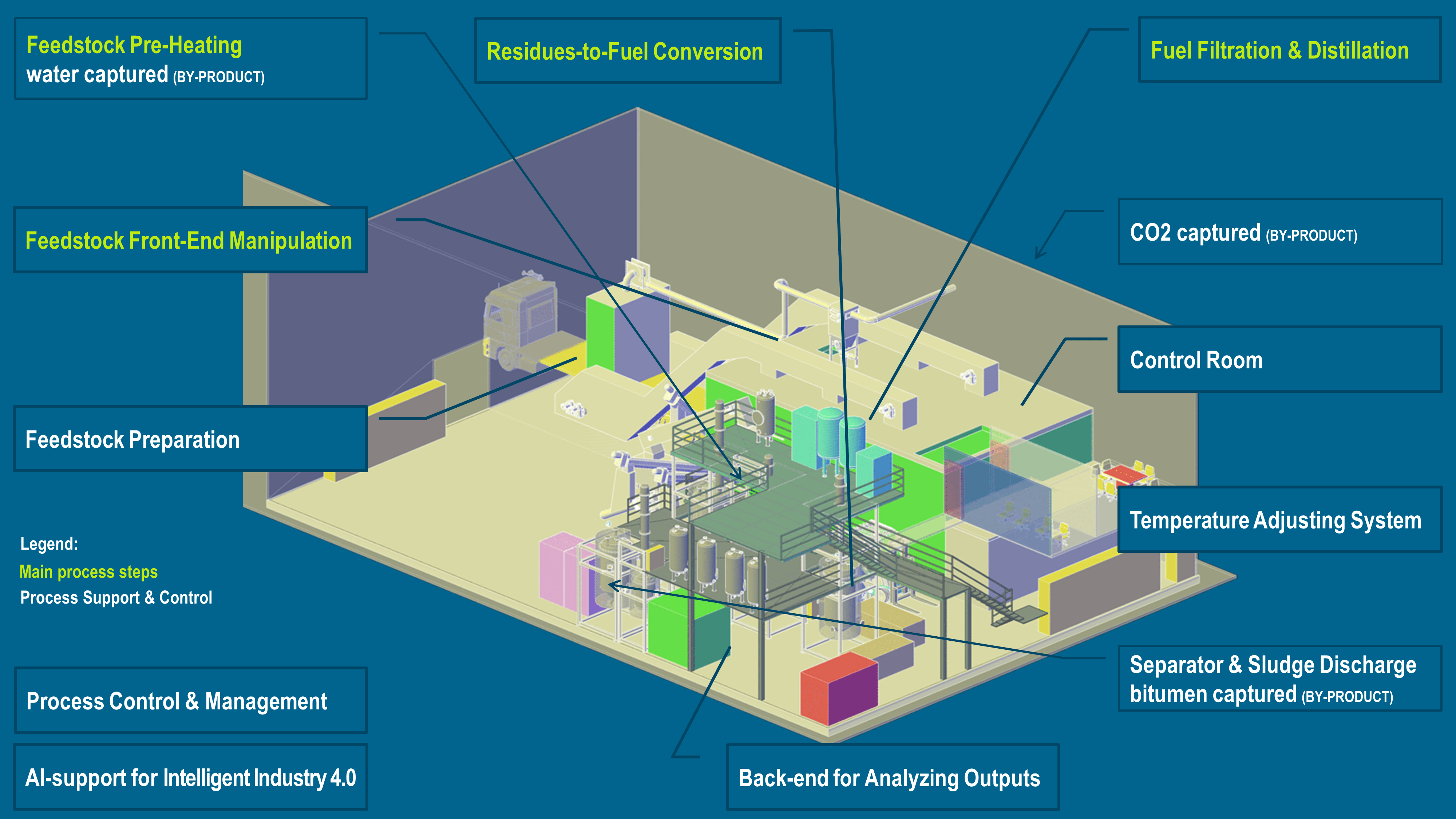

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.