Solution

SynDi Solution is not a silver bullet!

But it is a great opportunity to play a significant role in conserving the environment by tackling global, national, and local waste challenges. It accomplishes this by proven and reliable conversion of various hydrocarbon residues into high-quality alternative fuel.

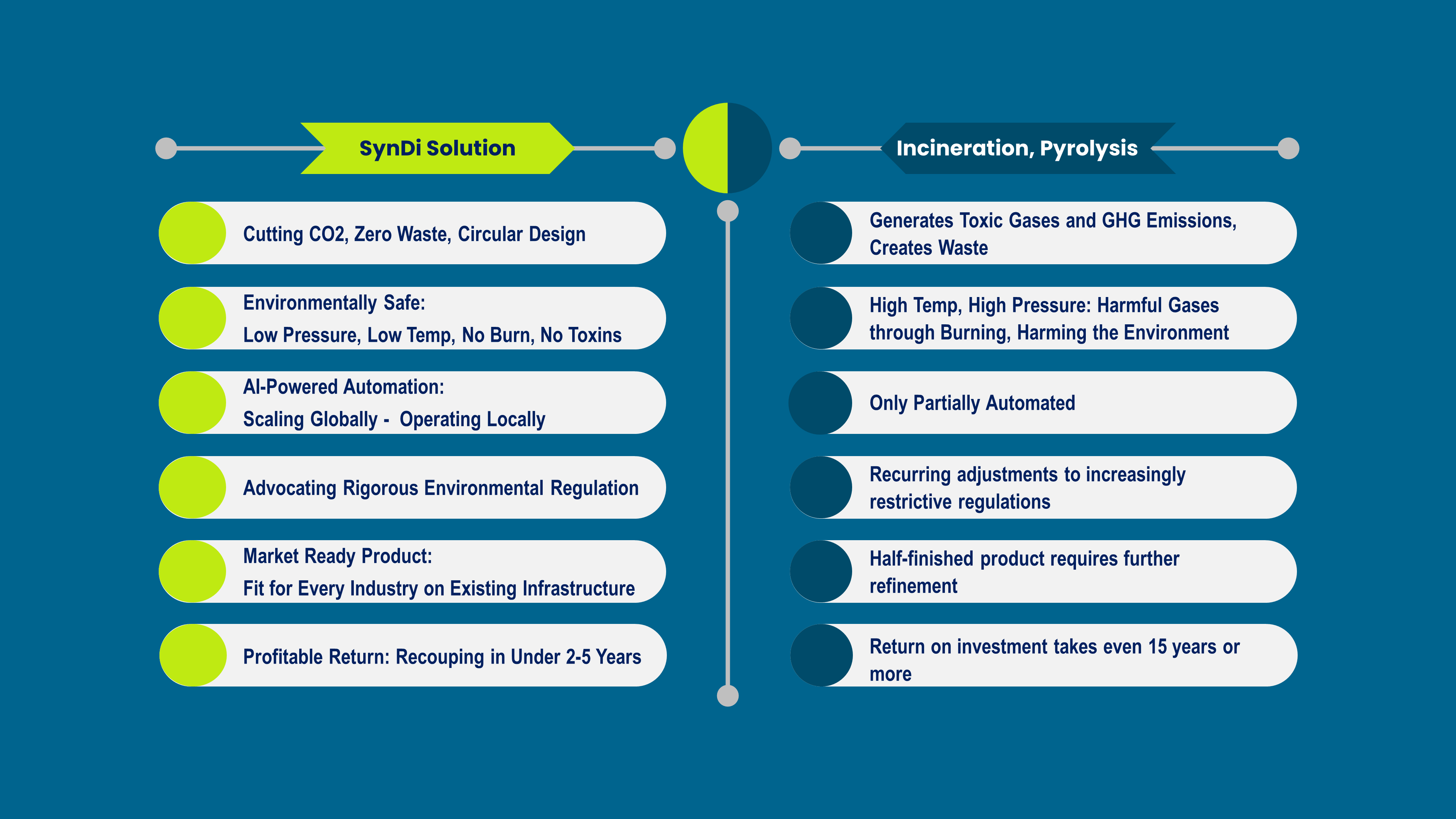

Its key competitive advantages include:

- eco - friendliness

- cost - effective reduction of CO2 emissions by even over 90%

- minimal energy consumption assuring low production costs comparable to fossil fuels

- rapid return on investment within 2 - 5 years

In a broader industry context, while the market primarily offers conventional methods, the theSynDi solution is a groundbreaking alternative for handling residuals. Unlike thermal splitting or cracking processes, such as incineration, gasification, or pyrolysis, which operate at high temperatures and pressures, SynDi Solution relies on a tribo-mechanical production process. This process involves heating and mixing feedstock at low temperatures (<320°C) without combustion and at low pressure (<1 bar). This distinctive approach sets it apart from traditional methods, offering enhanced efficiency and environmental benefits.

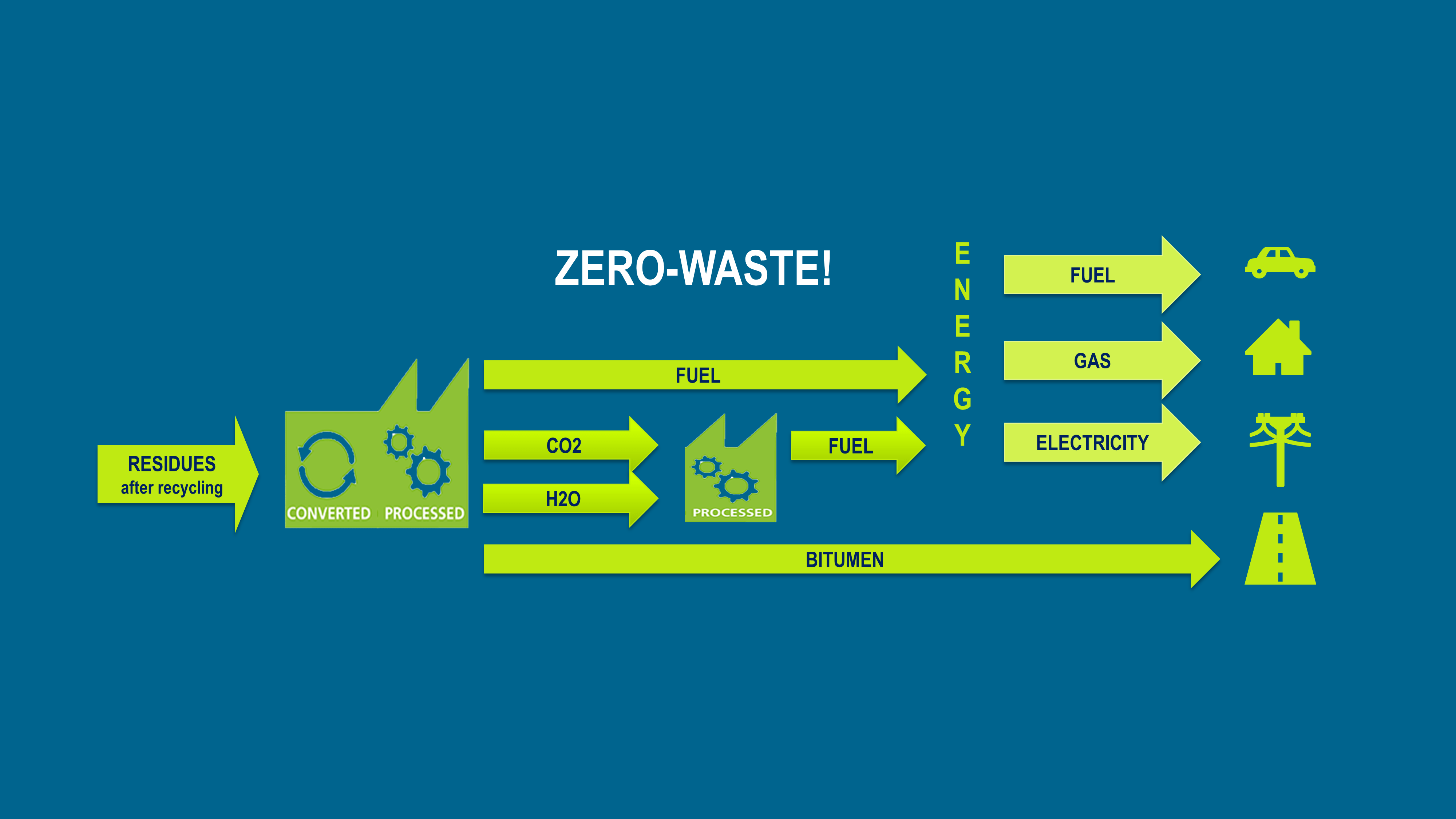

Remarkably, no additional water is required in the production process, and SynDi Solution is among the few solutions that actually produce water as a by-product.

This process mirrors the natural conversion of organic matter into fossil fuel but does so significantly faster, completing the transformation in just about 10 minutes. Thanks to its stable and robust nature, low-temperature operation, and absence of a burning process at low pressure, it achieves notably higher energy efficiency compared to thermal fuel production processes, with significantly reduced heat losses.

At its core, the tribo-mechanical process is designed to efficiently process a wide range of hydrocarbon-containing residues. These feedstocks can include materials such as wood, coal, oil, fuel, SRF, plastics, paper, rubber, textiles, yard trimmings, cultivated energy plants, agricultural residues, and weeds.

The conversion yield, achieving approximately 80%, is notably competitive.

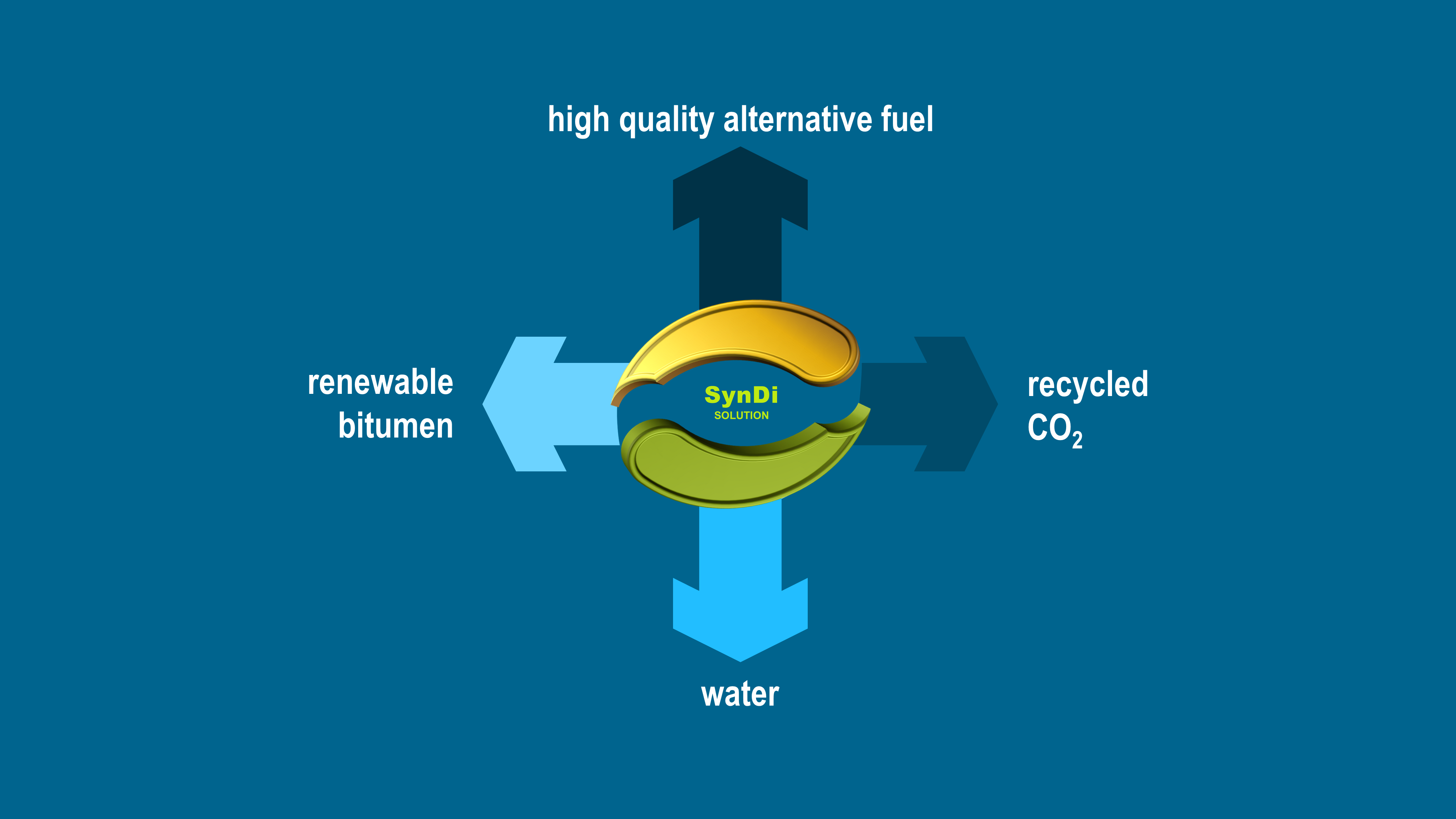

SynDi Solution yields four valuable products: high-quality sustainable alternative fuel, recycled CO2 from the feedstock, renewed bitumen containing inorganics, and water from feedstock humidity. Offering versatile applications across various industries makes SynDi a ZeroWaste solution.

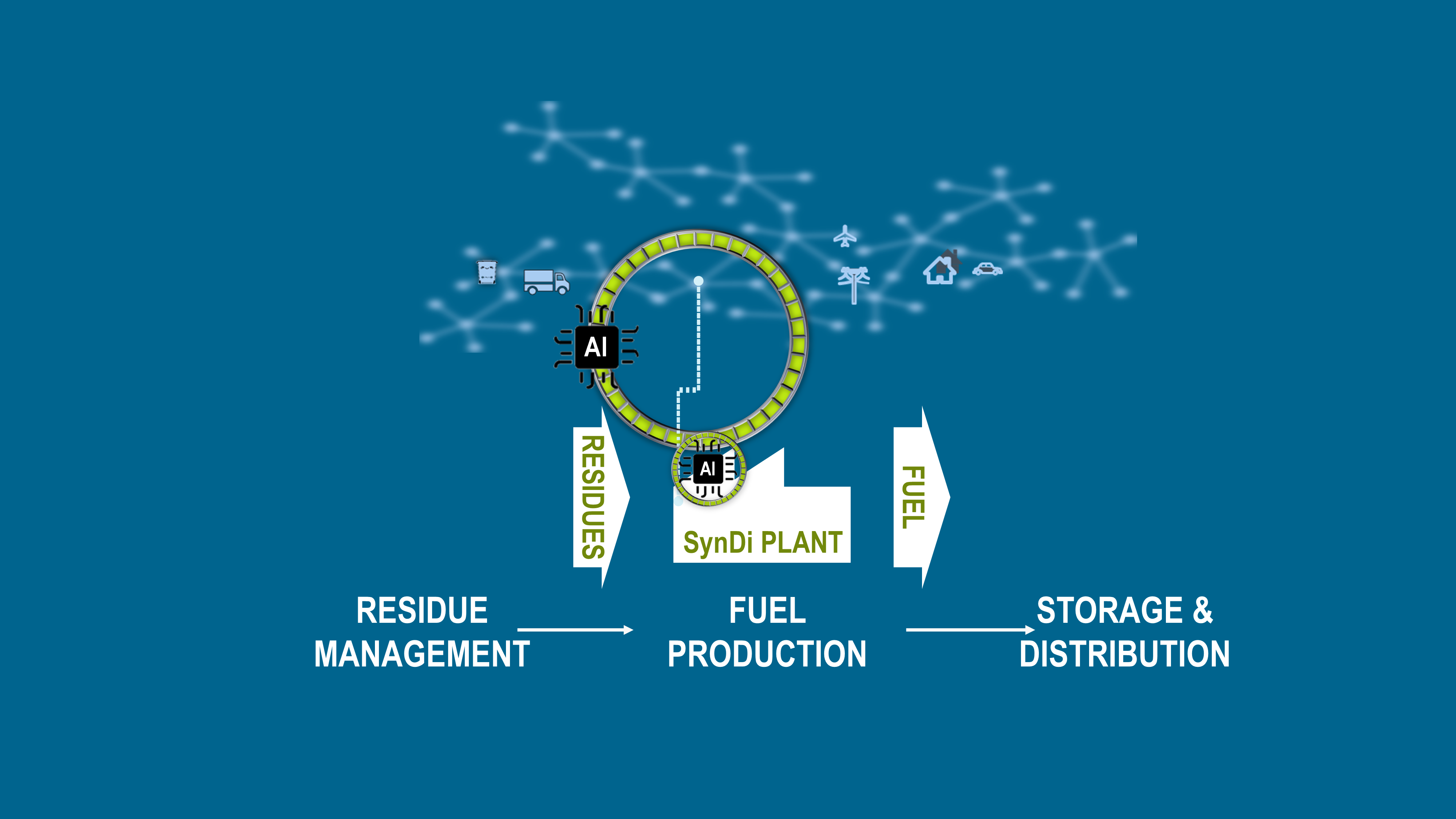

Leveraging advanced automation and AI, the plant operates as a self-sustaining and self-managed system, eliminating the need for extensive engineering support. This adaptability allows for installations in remote and rural areas globally.

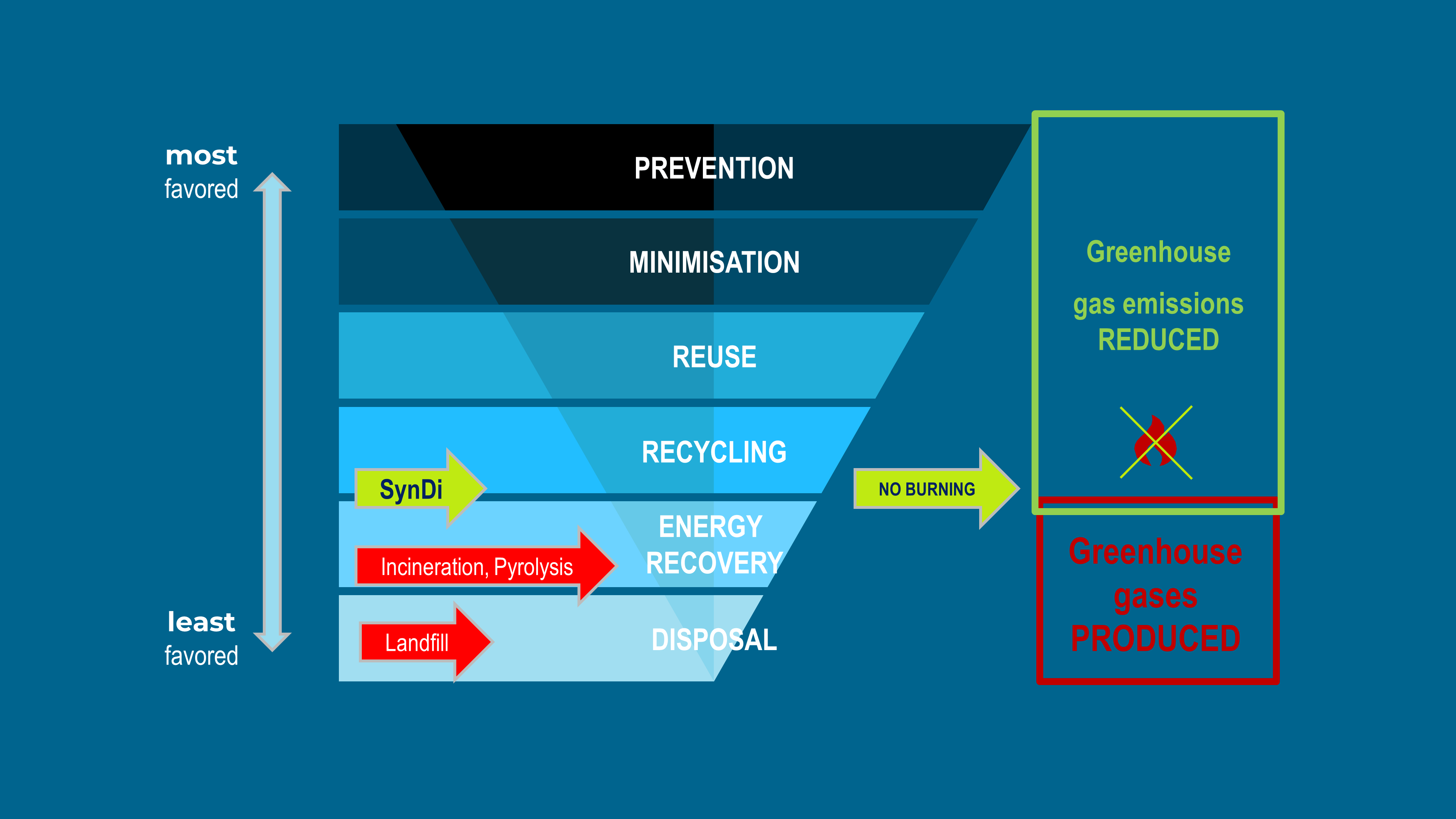

Given that SynDi Solution produces a ready-to-use marketable fuel, it can align with the waste management hierarchy as a form of chemical recycling, which enjoys a higher priority than all mentioned energy recovery technologies. This preference for recycling ensures priority access to residues.

Moreover, the storage, distribution, and utilization of the alternative fuel produced by SynDi Solution are straightforward, utilizing only existing infrastructure and is undemanding to the end-users.